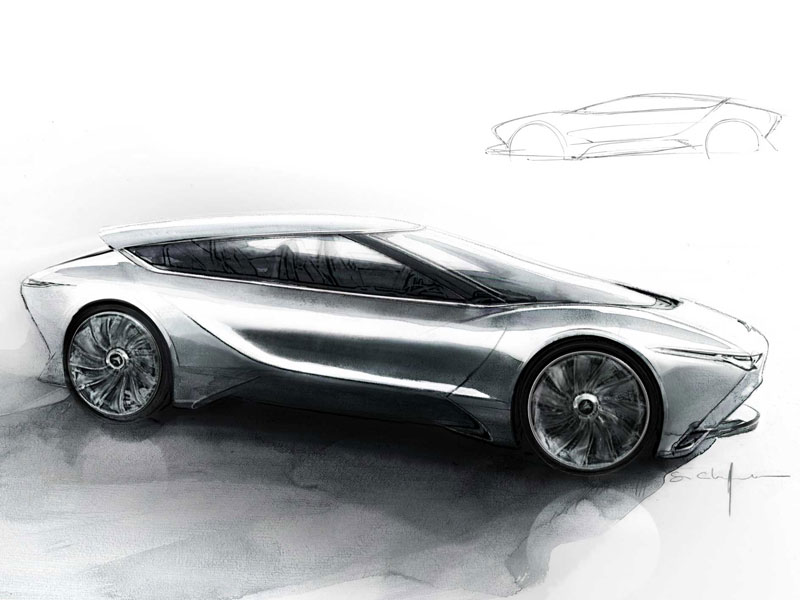

Da oltre 40 anni CECOMP dà forma alle idee sviluppate da designers,

centri stile, enti di ricerca & sviluppo per le case automobilistiche di tutto il mondo.

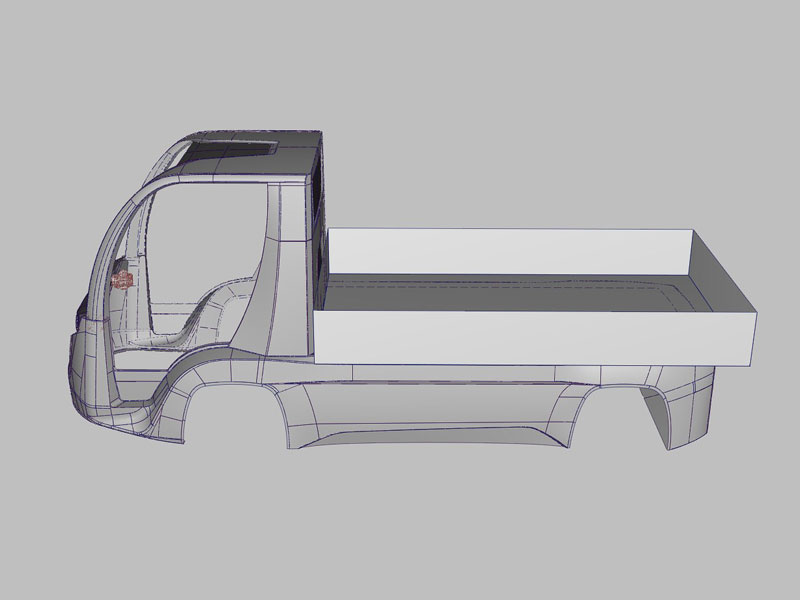

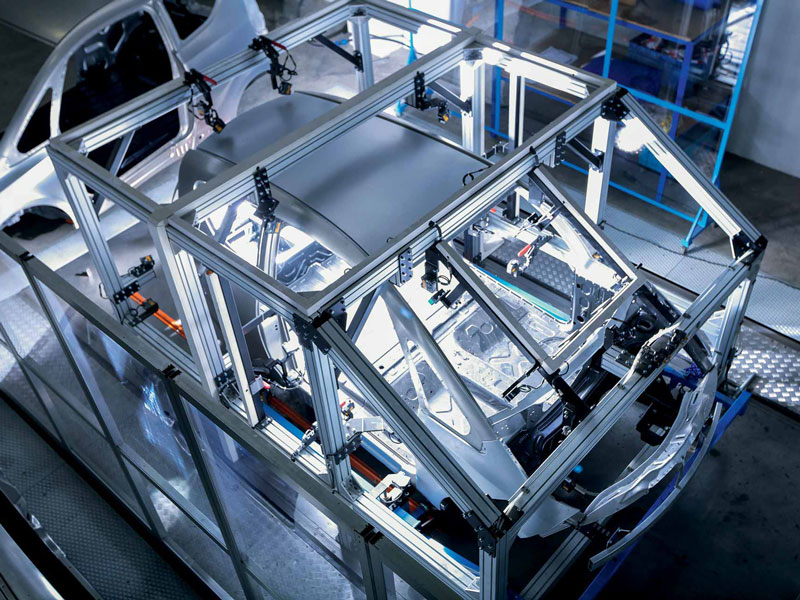

Supporta oggi tutte le fasi del ciclo di vita del prodotto:

definizione stile, realizzazione prototipi, pre-industrializzazione e industrializzazione, fornitura di parti, sistemi e veicoli completi per bassi volumi.